|

|

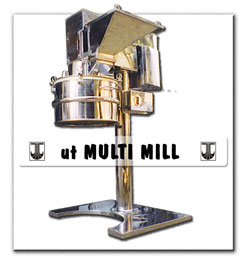

Drive

(3-phase) |

Capacity |

Screen size |

Total

Blades |

|

0.5

hp |

10 –

25 kg |

150 x

82 |

6+2

|

|

1 hp |

25 –

50 kg |

200 x

100 |

8+2 |

|

2 hp |

50 –

100 Kg |

225 x

120 |

10+2 |

|

3 hp |

100 –

200 Kg |

260 x

140 |

12+2 |

|

5 hp |

200 –

500 Kgs |

300 x

160 |

16+2 |

|

|

Salient Features

|

Uses |

: |

|

Model |

: STD / GMP

|

|

MOC |

: S. S. 304 Q. / 316 Q. (contact parts) |

|

Screen |

: Changeable type by means of quick opening and locking

arrangement. One screen provided along with

the machine

|

|

Capacity |

: Depending upon product (material density, nature, moisture

content, weight & screen mesh size) |

Optional accessories / attachments

-

Modified Straight Discharge Hopper (for maximum output rate of flow)

-

Dusting arrangement for pulverizing of fine powder to avoid dusting in the

air provided on Discharge Hopper with Perforated Bucket & Cloth

-

S. S. Jacket on Intermediate Hopper with inlet, outlet & vent connections

Recommended Spares

-

S. S. Screen - 0.5 mm to 20 mm

-

Special screens are available in # (mesh) in sandwich type

-

Rubber gasket- charging & discharging hopper

-

Teflon-ring / gasket

-

SS Blades set - cutting / scraper / swing / pins / beater boss / beater

cap

-

SS Blade – Hexsaw type cutter to increase the fines of the powdero SS

Beater / SS Shaft

|