|

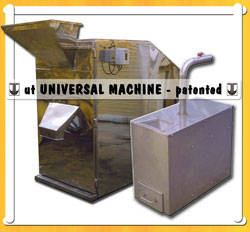

In our special category machineries, we present our PATENTED

TECHNOLOGY designed after an in depth study to be the only one of its

kind having most multi-purpose usage and versatile facility with improved

functional simplicity that is to train on, work with and maintain.

FIRST TIME IN INDIA an ALL IN ONE MACHINE with operations of:

-

ROASTING

-

MIXING

-

BLENDING

-

COATING

-

FLAVOURING

-

WASHING

-

DE-MOISTURIZING

-

SEASONING

|

|

Done within minimum time span depending upon the product, procedure &

capacity.

Easy operation CHARGING

PROCESS

. AUTOMATIC DISCHARGE

Special Features

1. Total compact machine

2. Vibration is completely eliminated. Noiseless

3. Maintenance free and easy to operate

4. Total operation without body contact with the product. Very Hygienic

Salient Features

1. Model : STD / GMP

2. MOC : S. S. 304 Q. / 316 Q.

2. Drive : 3 phase, 440V, 1440 RPM TEFC electric motor coupled with

reduction gear box & sprocket drum etc. with req. speed

Optional accessories / attachments

1. Castor Wheels for easy portability

2. Starter / control panel

3. Collecting Trays

4. Scoops, Scrapers, Stools/ Chairs

5. Auto Timer (for on/off)

6. Heating arrangement electrical elements

7. Auto digital control box

Processes especially for FOOD INDUSTRIES that can be performed in

single unit

OASTING / WASHING

Seeds, Soya dal, Soya, Nuts, Cashew nuts, Ground nuts, Almond, Spices,

Suji, Mong dal, Teel seeds, Dry Fish, Wheat, Velchi,

Onion Flakes, Supari, Granules, Tea, Coffee, Saunf, Dal, Dhana, Rice,

Chana, Vegetable (except leaves) etc.

DE-MOISTURIZER

Nuts, dry fruits, seeds, chiwda, farsan, namkeen, wafers, etc.

MIXING / BLENDING

Powders, Spices, Granules, different kinds of Chiwda-Bhel, Hing

(asafetida), Mixed spices

FLAVORING

Namkeen, Waffers, Chiwada-Bhel, kinds of nuts, supari, and all products

mentioned above.

SALTING / SEASONING / COATING / COLORING

Wafers, Dhana dal, Mukhwas, saunf, Seeds, Nuts, Prawns (fish), Dhoop,

Rice, etc.

Capacity and Prices may

vary depending upon product and subsequent required process

|

Process MIXING |

|

Cap /

Batch |

Cap /

Hr. |

Drive-3ph |

Dimensions |

|

01 kg |

25 kg |

0.25 |

1 x

1.2 x 1.5ht |

|

02 kg |

50 kg |

0.5 |

1.2

x 1.5 x 2ht |

|

03 kg |

70 kg |

0.5 |

1.5

x 2 x 2 ht |

|

05 kg |

90 kg |

0.5 |

3 x

3 x 2 ht. |

|

10 kg |

150

kg |

1.0 |

4 x

3 x 4 ht. |

|

15 kg |

200

kg |

1.0 |

4.5

x 4 x 4 ht. |

|

20 kg |

250

kg |

1.5 |

5 x

5 x 4 ht. |

|

25 kg |

300

kg |

1.5 |

6 x

6 x 5 ht. |

|

30 kg |

350

kg |

2.0 |

10 x

8 x 8 ht. |

|

50 kg |

500

kg |

3 |

10 x

9 x 9 ht. |

|

Process

- ROASTING |

|

Capacity |

05 kg |

10 kg |

20 kg |

30 kg |

50 kg |

100 kg |

|

Drive - 3 ph |

0.5 hp |

1 hp |

1.5 hp |

2 hp |

3 hp |

5 hp |

|

Time* |

15 mins |

20 mins |

25 mins |

45 mins |

55 mins |

60 mins |

|

Dimensions |

3' x 2' x 3' |

4' x 3' x 4' |

5' x 4' x 5' |

6' x 5' x 6' |

7' x 6' x 8' |

9' x 7' x 10' |

|

Model - A |

Only Roasting process |

|

Model - B |

Roasting incl heating coil/electrical |

|

Model - C |

Roasting incl heating media, coil / electrical,

auto control box) |

|